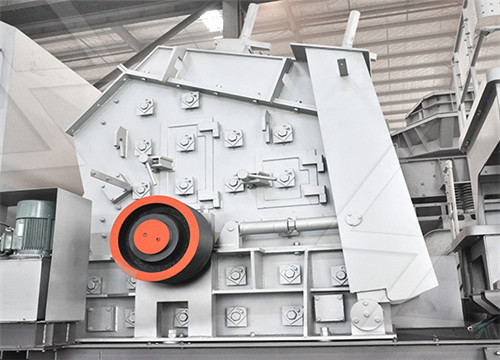

impact crusher

IMPACT CRUSHERS

IMPACT CRUSHERS. PRIMARY IMPACT CRUSHER HPI; Primary Impact Crusher HPI-H; Secondary Impact Crusher HSI; Tertiary Impact Crusher HTI; Compound Impact

进一步探索

Spare parts Products Hazemag North America

冲唤破碎机 百度百科

2023年5月5日 Impact crusher is widely applied in mining, transportation, energy, construction and chemical industry. Impact crusher is ideal choice for crushing and

进一步探索

什么是冲击式破碎机(Impact Crusher)? IIIFF互动问答平台【Impact Crusher】的中文翻译和相关专业术语翻译-SCIdict

Impact Crushers

2 之 impact crushers are designed to excel as primary impactors, taking large feed material and reducing it down to a sellable product. They’re also extremely

Impact Crusher Machines Williams Patent Crusher

Easy Maintenance Williams machines have been designed with easy maintenance requirements to increase efficiency and decrease overall costs. Our impact crushers are

Primary Impact Crushers MEKA

Primary Impact Crusher. MEKA MPI crushers, offering high reduction ratios, reduced power consumption, easier and safer maintenance are the solution for operating conditions where output and productivity demands are

Impact Crusher Working Principle 911 Metallurgist

2015年6月23日 Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding method. Shear crushing is accomplished by breaking along or across lines of cleavage. It is possible, when required,

McLanahan Impact Crushers Primary

McLanahan offers a wide selection of Impact Crushers for quarried limestone and semi-abrasive minerals. McLanahan draws from the 75 years of field experience with the

How Impact Crushers Work: A Comprehensive

2023年3月11日 An impact crusher is a machine used to crush materials by impact energy. It works by feeding the material into a rotating rotor, which is equipped with a series of hammers. As the rotor spins, the hammers

Mobile Impact Crushers RUBBLE MASTER

Mobile impact crushers are used to recycle concrete and asphalt and process natural rock. They are easy to move on and between job-sites, which allows operators to crush on smaller job-sites. Best of all they

Impact Crusher for Soft Materials DASWELL

2023年7月1日 Impact crusher is a kind of stone crusher. Due to its structural design, the crushed finished particles are mostly cubic in shape. Impact crusher is suitable for all kinds of coarse, medium and fine materials whose compressive strength does not exceed 350Mpa. Because its discharge size can be adjusted, it can meet the needs of different

What is an Impact Crusher? ZENITH Crusher

2021年12月9日 What Is An Impact Crusher? The Aggregate Industry (Cement, Ready-Mix Concrete, Asphalt, Crushed Stone, SandGravel), wants to process rock, sand, and gravel into a salable product as efficiently and inexpensively as possible. One such way to process these materials is sending gravel, rock, and sand through an Impact Crusher, which

Mobile Impact Crushers RUBBLE MASTER

Save up to 30% in fuel with ourdiesel-electric direct drive. RUBBLE MASTER mobile impact crushers use a proven and powerful diesel-electric drivetrain. Contrary to many traditional crusher manufacturers RUBBLE

Impact Crusher آسیا ماسه ساز

Impact Crusher. Impact Crushers are impact or rotary crushers which crushing is done by hammers. High mechanical power and high speed of Impact Crusher, produce uniform production. Crushing in Impact crushers is Impact, in this way when the material enter to the impact crusher the rotar in rotating position rotates the hammer.

Primary Impact Crushers MEKA

Primary Impact Crusher. MEKA MPI crushers, offering high reduction ratios, reduced power consumption, easier and safer maintenance are the solution for operating conditions where output and productivity demands are increasingly stringent. The strength of MPI crushers makes them ideal for diverse applications and configurations. These crushers

Study of the wear behavior of limestone impact crusher blow bar

2020年6月18日 This contributes to about 60 % of the cost of wear parts in an impact crusher. This study is focus on wear analysis of rotor blow bars of a compound impact crusher used in limestone crushing. The

(PDF) A performance model for impact crushers

2002年10月1日 Abstract and Figures. In this stone we develop a performance model for impact crushers. The product size distribution is obtained as a function of the crusher’s rotor radius and angular velocity

Impact Crushers Armstrong Industries

GRB 777 Mini Impact Crusher. Sold Out View. GRB 777 XL Impact Crusher. From $6,500 View. IC100 Impact Crusher. $57,500 View. IC120 Impact Crusher. $68,500 View. IC150 Impact Crusher. $82,800 View. IC160 Impact Crusher.

Impact Crusher Rock Crusher Machine Manufacturer JXSC

The impact crusher is widely used for sand and rock fine crushing in the industry of roads, railways, reservoir, electricity power and building materials and so on. And the compressive strength less than 350 MPa. 3. Working Principle Jaw rock crusher does cyclical movement by swinging jaw to crusher rock. But impact stone crusher use of impact

New or Used Impact Crusher for sale Australia Machines4u

New and Used Impact Crusher insights. There are 41 Impact Crusher for sale in Australia from which to choose. Overall 52% of Impact Crusher buyers enquire on only used listings, 45% on new and 7.12% on both new and used Impact Crusher items.Buyers usually enquire on 1.79 different Impact Crusher classifieds before organising finance.

ROCK PROCESSING EQUIPMENT AND SOLUTIONS — SRP

A world leader in rock processing solutions for the mining and construction industries. Our constantly evolving offering for mining and construction covers crushing, screening, breaking, demolition and service solutions. No matter the application, we'll ensure you're matched with the right solutions to maximize your productivity and profitability.

Impact Crushers: HorizontalVertical Shaft Ritchie List

1998 Eagle Crusher 1000-15CV Impact Crusher. Wayne, Michigan-$129,900 USD. Listings by Construction Station. 2021 Metso LT106 Impact Crusher. Bloomfield, New Mexico. 982 hrs. $580,951 USD. Listings by WAGNER EQUIPMENT CO. 2021 Metso LT200HP Impact Crusher. Albuquerque, New Mexico. 997 hrs. $584,490 USD.

Impact Crusher, Horizontal Shaft Impact Crusher GEP

2023年7月21日 The impact crusher uses horizontal and high-speed moving rotors to crush materials, which can help the producer to obtain a fine-grained and evenly distributed product. Impact crushers are widely used in the production of construction aggregates and crushing construction and demolition waste. GEP Ecotech's impact crusher uses high

Impact crusher structure, working principle and features

2021年9月2日 1. Impact crusher structure. 1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the single rotor impact crusher (Figure 1) is relatively simple and consists mainly of the rotor 5 (strike plate 4), the impact plate 7 and the machine body. The

Jaw Crusher VS Impact Crusher (A Comparison from 7

2020年2月28日 1. Application. 1. Jaw crushers are mainly used as primary crushers, it can crush hard material, such as granite, basalt. 2. Impact crusher is usually used as a medium-fine hardness crusher, such as limestone, concrete, it has good crushing efficiency of some brittle material. It mainly crushes the small material discharge from the jaw crusher.

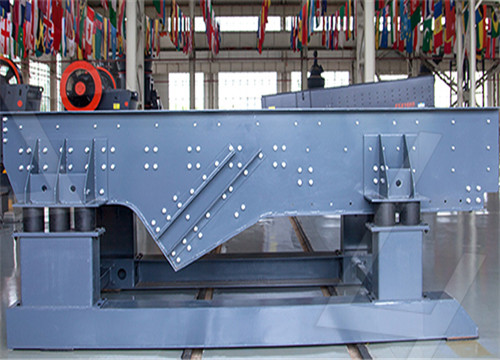

Portable Impactor Plants Aggregate Equipment -Milwaukee

1 ’s wheel-mounted portable impactor plants provide a high-production, cost-effective HSI crusher on a rugged truck frame. These portable plants are equipped with heavy-duty mplgrizzly feeders sized for optimal throughput. Plants are customized with various discharge methods including conveyor belts of varying length or vibrating

How Impact Crushers Work: A Comprehensive Guide AGICO

2023年3月11日 An impact crusher consists of several components, including the rotor, hammers, impact aprons, and screens. The rotor is the central part of the machine, and it is the part that rotates and drives the hammers. The hammers are attached to the rotor by means of a pivot point, which allows them to move freely and strike the material with

Simulation of particle flows and breakage in crushers using

2015年4月1日 The final impact crusher type to be considered here is a horizontal shaft impactor (HSI). This type of crusher shares several aspects with the hammer mill but with key differences that give it different performance characteristics. The CAD model for a Cedarapids style HSI (Young et al., 2003) is shown in Fig. 19. The central rotor (dark